Quick Details

Condition: New

Type: jet grouting drilling rig

Power Type: Diesel

Place of Origin: Jiangsu, China (Mainland)

Brand Name: xitan

Model Number: XPG-65

Usage: geology engineering

Voltage: 380V

Power(W): 55+11+3

Dimension(L*W*H): 6.385*3.34*2.75m

Weight: 8200kg

Certification: ISO9001:2008

Warranty: 6 Months

After-sales Service Provided: Engineers available to service machinery overseas

Model: XPG-65

Hole Depth: 150-180m

Hole diameter: 150-250

rod diameter: 73,89,102,114mm

Hole angle: 0-90°

Lifting force: 66KN

feeding force: 34KN

Stroke of power head: 4000mm

Output torque of power head: 5800NM

Output rotary speed of power head:0~12,0~25,30,60,75,120,150

Quick Detail:

1. XPG-65 drilling rig is one kind of full hydraulic power head drilling rig.

2.The assistant tower of XPG-65 jet grouting drill rig is high, which achieves 20 m,it can ruduce the time to

add and wrench the tools.

3. Because of big torque, the depth of high pressure jet grouting drilling rig is deeper. Depending on big power, this rig can be applicable for more engineering construction.

4.The assistant tower can be made up of 4 parts,can be reached 5m,10m and 20m.

Description:

1. XPG-65 drilling rig can accomplish drilling hole and jet grouting process in once time when operating in some certain soft layer. During the jet grouting lifting, the depth of the rotary jet shall not exceed the height of the assistant tower (20m). There is no need to dismantle the drill rod.

2. With good adaptability, this jet grouting drilling rig can be configured with different modules and drilling tools, so as to solve various jet grouting processes.

3. Besides jet grouting process, this jet grouting drilling rig is available for the construction of anchoring technology.

4.Using the hydraulic chuck,it is easy to change the tools,do not need the joint.

5.The shifting and turning of the drill rig, speed change of power head and drill lifting are all adopted hydraulic control, featuring in flexible operation, saving time and labor cost.

6.The drill rigs adopt double winches and electrical control which can reduce labor force and enhance production efficiency.

Applications:

1. For jet-grouting and anchoring

2. Soft ground stabilization, seepage control of basement of high-rise buildings, renovation of big river and levee, reinforcement of railway, highway and pier, etc.

3. Singe pipe, duplex pipe, triple pipe

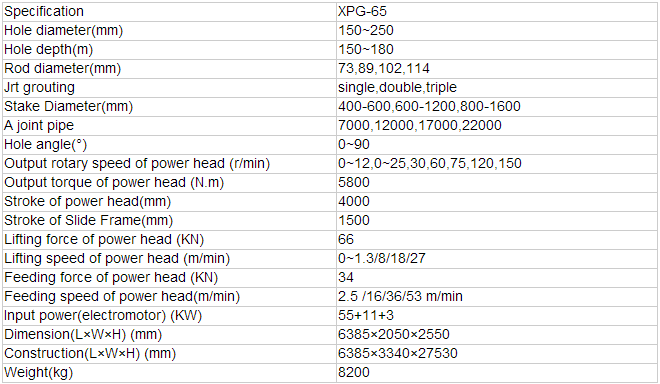

Specifications: